Yes, you need to program the TO/FROM instructions to get the value from the card. I have only used these but there is another way explained in the manual.

The card uses buffer memories to send/receive data to/from the card these are called BFM registers. Some are used to set the type of analog & other settings others are to read the values or status etc.

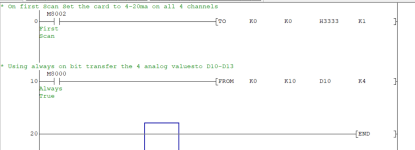

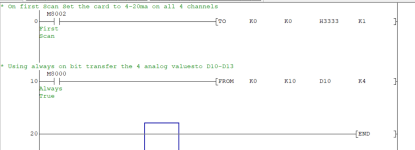

so first of all in the program you do a TO instruction to set the card type for example to set the card to 4-20ma you do a TO instruction sending a Hex value of H3333 this would set all channels to 4-20ma. or you can set different channels to different types i.e. 4-20 0-10v and the resolution etc. see manual.

So on a first scan using M8002 (First scan)

AND M8002 [TO K0 K0 H3333 K1]

K0 This sends to card 0 (first card in expansion)

K0 to BFM 0 (Setting of analog input)

H3333 4-20ma (setting range)

K1 Send 1 word

The FROM instruction reads the analog values

So

AND M8000 (Always on bit) so reads every scan

[FROM K0 K10 D10 K4]

K0 Reads from card 0

K10 Analogue values starting at BFM 10

D10 into D10 to Dxx (so reading all 4 channels to D10 to D13)

K4 Number of channels to read.

Even if you are not needing all channels no problem reading all 4.

Here is the link to the manual

https://www.allied-automation.com/w...X3U-Users-Manual-–-Analog-Control-Edition.pdf

Attached is a program that shows how to set up & get the values from the analogue card.

You need to adapt the values depending where the card fits on the expansion.

There are over 180 buffer memories but only a few need to be used. if you want to scale the values coming back then you can do the maths to scale them.

Also to see the values change on the HMI you just need to add an analogue value field to the display & give it an address i.e. for channel 1 in the example D10