khaja nazeeruddin ik

Member

hello

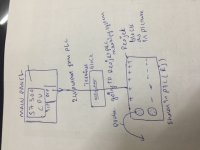

i am using siemens s7 300 for handling the system .we are going to add marking system which is having inbuilt plc in it ,just i have to give 24 v output from my main plc s7 300 to start trigger marking as you can see in picture (rj)

i made one output high in my main plc so i am getting 24v.

i am having 8 core cable coming from my main plc panel to terminal block in which all 7 wires are used for input and 8 wire i am using as output to take 24 volts from main plc panel to this machine.i am getting only single wire for 24 v

do i need the return path for 24v or i have to connect only 24v on the picture for plus 24 volts (rj) no need to connect on negative side

for this 24v i need to connect 24v plus side and minus side i can connect it to ground r what i dont understand

please let me know do i need to connect negative 24 to complete the path

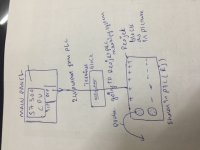

i am using siemens s7 300 for handling the system .we are going to add marking system which is having inbuilt plc in it ,just i have to give 24 v output from my main plc s7 300 to start trigger marking as you can see in picture (rj)

i made one output high in my main plc so i am getting 24v.

i am having 8 core cable coming from my main plc panel to terminal block in which all 7 wires are used for input and 8 wire i am using as output to take 24 volts from main plc panel to this machine.i am getting only single wire for 24 v

do i need the return path for 24v or i have to connect only 24v on the picture for plus 24 volts (rj) no need to connect on negative side

for this 24v i need to connect 24v plus side and minus side i can connect it to ground r what i dont understand

please let me know do i need to connect negative 24 to complete the path