Peter Nachtwey

Member

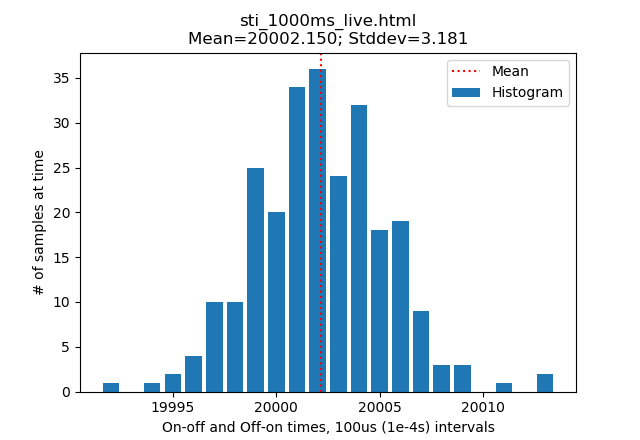

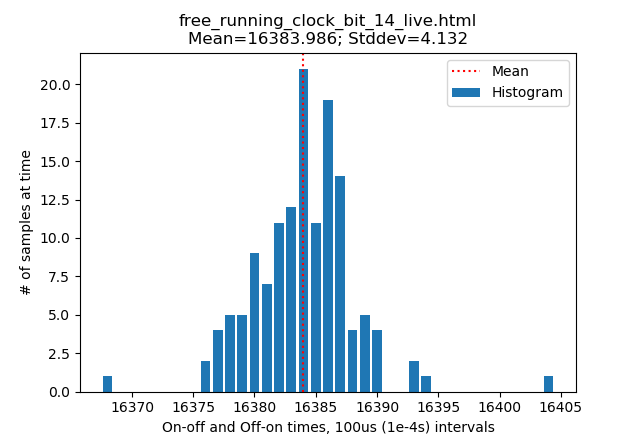

sampling data.

I will probably use this in a magazine article.

I will probably use this in a magazine article.

sampling data.

I will probably use this in a magazine article.

I might be missing the point, but most applications 99/101ms is negligible.

I might be missing the point, but most applications 99/101ms is negligible. As others have pointed out, using the continuous count with subtracting time and eventually subtracting magnitudes will run for years.

What application is this for?

Yes, sometimes they will run long if the interrupt occurs during house keeping time where the interrupts are turned off but the next interrupt is still generated by hardware so the next interval will be shorter.In A-B-ville, timed Interrupts are better than timers, but they still run long, the same as timers. Using an internal clock, if available, is the only reliable method to get a mean period that is correct.

The hardware will generated interrupts and even intervals so the there will be no accumulated error when it comes to time.

Where is your hard evidence?Based on hard evidence I can't agree; I am sure that is what is supposed to happen, but in reality it does not, as the github repo documents my physical experiments. It is definitely not the case in the MicroLogix 1xxx line (or at least with my 1100, serial number ...')), but that does not say anything about other PLCs. In any case it would be difficult to measure to that level of precision in higher-end A-B hardware, as I don't see easy access to a 10kHz free-running counter or equivalent (I think either SLC or PLC-5 may have it).

Where is your hard evidence?

What micro controller are you talking about that can't generate interrupts are consistent intervals.

SHOW US!

... However, I don't think it addresses the timed interrupt method under discussion.