Hello,

I have a machine that had an SLC 5/02 with Link Coupler, DTAM, etc. and the processor and power supply failed, losing the program. Tried going to the OEM, but the 5/02 is obsolete, so an easy upgrade is a 5/03, right? Well, i got the program loaded, and the DTAM sort of works.

Previously, the DTAM would display a message like "Enter Timer #" and it would allow the operator to select one of 18 or so different timer functions; pressing timer 1 would display "cooling delay 2600" which was 26 seconds preset on T4:2, and you could change the value there, pressing next would get timer 2, etc.

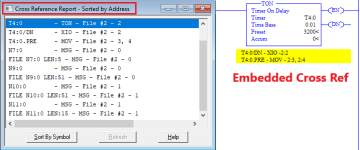

My question is if I wanted to use a simple HMI to replace the outdated 5/02 and DTAM hardware, what destination can I tell the HMI to send the new value to?

Would it be T4:2 Preset?

Or an Integer?

I ask because the ladder logic shows a lot of N7:230's, B3:6's, and only a couple of MSG instructions. I've done a bit of programming, but nothing involving the DTAM, which is decades old. Shame it stopped working because those things were rock solid.

thanks in advance

I have a machine that had an SLC 5/02 with Link Coupler, DTAM, etc. and the processor and power supply failed, losing the program. Tried going to the OEM, but the 5/02 is obsolete, so an easy upgrade is a 5/03, right? Well, i got the program loaded, and the DTAM sort of works.

Previously, the DTAM would display a message like "Enter Timer #" and it would allow the operator to select one of 18 or so different timer functions; pressing timer 1 would display "cooling delay 2600" which was 26 seconds preset on T4:2, and you could change the value there, pressing next would get timer 2, etc.

My question is if I wanted to use a simple HMI to replace the outdated 5/02 and DTAM hardware, what destination can I tell the HMI to send the new value to?

Would it be T4:2 Preset?

Or an Integer?

I ask because the ladder logic shows a lot of N7:230's, B3:6's, and only a couple of MSG instructions. I've done a bit of programming, but nothing involving the DTAM, which is decades old. Shame it stopped working because those things were rock solid.

thanks in advance