Archie,

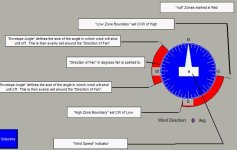

That looks almost exactly what I'm looking for. There are instances when the evaporators can run within a "null" zone, if wind conditions remain low for a timed period. I thought I'd also place a visibility tag to remove the arcs if operating in that condition. While I very much like AdvancedHMI, and do use it from time-to-time, these evaporators are a bit out away from the rest of the plant, and are not networked to the rest of the control system.

I think I was a bit confusing when I said "software package"....I only meant panel configuration software. There are no place to install PC interface to the evaporators, hence using a manufactured hardware panel.

I have toyed with the idea of installing a yagi antenna to a wireless network radio to communicate back to the plant control system. If so, Archie, your solution would be perfect.

I have Red Lion G3 software, and hadn't seen an arc or wedge fill, but will look into it as well for panel configuration.

I'm not familiar with Maple Systems, but if it works with the Micro800 series PLC, it should also work with a Micrologix1400.