Sean Teague

Member

Hey guys,

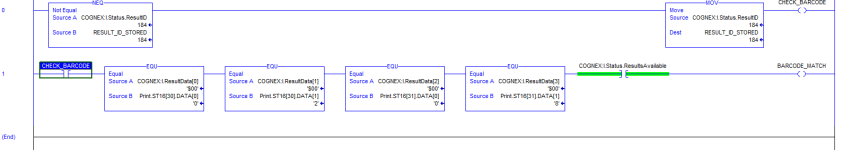

I have an older Cognex Dataman scanner that i have added to a machine. I have established comms over ethernet. I am able to trigger manually and receive data from the scanner. So heres my problem:

My barcode is the current date.

Im getting the data back from the scanner into these locations

COGNEX:I.ResultData[0] '0'

COGNEX:I.ResultData[1] '2'

COGNEX:I.ResultData[2] '0'

COGNEX:I.ResultData[3] '8'

then im comparing it to the current date in the PLC.

If this data compares correctly im setting an output BARCODE_MATCH

im having trouble "clearing" COGNEX:I.ResultData[0], COGNEX:I.ResultData[1], COGNEX:I.ResultData[2], COGNEX:I.ResultData[3] later in the logic. I have tried to MOVE a "0" into these locations but once i stop movng the "0" into those locations, they automatically populate with the data from the last scan...Im trying to basically clear out the memory to be ready for the next scan....

I have an older Cognex Dataman scanner that i have added to a machine. I have established comms over ethernet. I am able to trigger manually and receive data from the scanner. So heres my problem:

My barcode is the current date.

Im getting the data back from the scanner into these locations

COGNEX:I.ResultData[0] '0'

COGNEX:I.ResultData[1] '2'

COGNEX:I.ResultData[2] '0'

COGNEX:I.ResultData[3] '8'

then im comparing it to the current date in the PLC.

If this data compares correctly im setting an output BARCODE_MATCH

im having trouble "clearing" COGNEX:I.ResultData[0], COGNEX:I.ResultData[1], COGNEX:I.ResultData[2], COGNEX:I.ResultData[3] later in the logic. I have tried to MOVE a "0" into these locations but once i stop movng the "0" into those locations, they automatically populate with the data from the last scan...Im trying to basically clear out the memory to be ready for the next scan....