40mpg

Member

Hello,

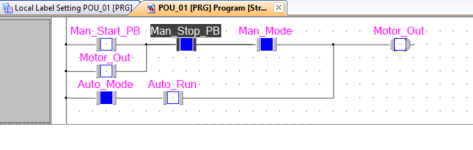

I am trying to write a logic to control a pump. I have my logic as attached. Is there a way to do Auto and Manual control without having two rungs with two OTE?

In Auto - pump will start if Tank high level alarm triggers, will start if user "kick start" the pump. The pump will stop if tank low level alarm triggers or E_STOP is trigger

In Manual - user can start the pump, pump will stop if user press stop button or E_STOP condition triggers.

Is there a way to combine the two in one rung?

I am trying to write a logic to control a pump. I have my logic as attached. Is there a way to do Auto and Manual control without having two rungs with two OTE?

In Auto - pump will start if Tank high level alarm triggers, will start if user "kick start" the pump. The pump will stop if tank low level alarm triggers or E_STOP is trigger

In Manual - user can start the pump, pump will stop if user press stop button or E_STOP condition triggers.

Is there a way to combine the two in one rung?