tomwhite007_2008

Member

Processor = Control Logix 5000

Drive= AB PowerFlex 70

Communication = DeviceNet

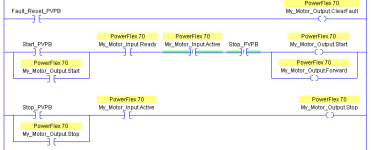

I am writing a program off-line am not able to test it. My Question is I want to Start a VFD and keep it running. Do I have to maintain "MY_MOTOR.O.Start" high as long as I want the motor running or does it just have to be pulsed to Start it to keep it running? See the Logic below. Will my motor continue to run if I take my finger off the PanelView Push Button "START_PVPB"?

Drive= AB PowerFlex 70

Communication = DeviceNet

I am writing a program off-line am not able to test it. My Question is I want to Start a VFD and keep it running. Do I have to maintain "MY_MOTOR.O.Start" high as long as I want the motor running or does it just have to be pulsed to Start it to keep it running? See the Logic below. Will my motor continue to run if I take my finger off the PanelView Push Button "START_PVPB"?