Hi -

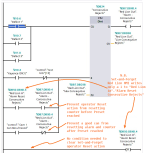

I was after a bit of feedback on the alarm resetting logic Im using in a Redlion HMI and 1200 PLC

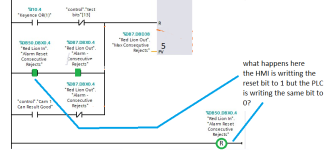

When the "alarm consecutive rejects" (light blue box -coil) goes true - I raise an alarm in the RL - when an operator hits accept button on the alarm page I write the reset contact (dark blue box NO) to 1.

When the "alarm consecutive rejects" (light blue box -coil) goes false I wait 150ms and write the reset contact (dark blue box NO) to 0.

This seems to work fairly well - but I haven't tested extensively - anything I've overlooked?

I know there are alot of other RL users on here so I just wondered what other people did, or if there was some convention used for alarm resetting via HMI / PLC.

Kind Regards

e2a - this was some test code Im not using raw inputs on machine program

I was after a bit of feedback on the alarm resetting logic Im using in a Redlion HMI and 1200 PLC

When the "alarm consecutive rejects" (light blue box -coil) goes true - I raise an alarm in the RL - when an operator hits accept button on the alarm page I write the reset contact (dark blue box NO) to 1.

When the "alarm consecutive rejects" (light blue box -coil) goes false I wait 150ms and write the reset contact (dark blue box NO) to 0.

This seems to work fairly well - but I haven't tested extensively - anything I've overlooked?

I know there are alot of other RL users on here so I just wondered what other people did, or if there was some convention used for alarm resetting via HMI / PLC.

Kind Regards

e2a - this was some test code Im not using raw inputs on machine program