You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Current Meter Recommendations

- Thread starter afm

- Start date

danw

Lifetime Supporting Member

I have had one bad AC current transducer in a batch of 12, so it can happen.

The transducer output is an active output so you'd think you'd get 4mA with no current on the sensed wire. But . . . .

1. The I/O module has the 4-20mA (-) connect to the L(-) terminal. If the 4-20mA is not an isolated output (which I doubtt given that terminals 2 & 3 are tied together on the transducer), you could have a ground loop problem between the transducer DC supply/transducer 4-20mA return and the I.O L(-).

Is there some reason you're not using the I/O modules L(+) for DC power to the transducer? The DCT100 needs 2VA or 85mA

2. The transducer is measuring DC current and the instructions are specific that the current flow must match the arrow on the device.

Is current flow (+) to (-) or (-) to (+)? Somehow, they forgot to specify and I'm old enough to remember debates about current flow, so I don't know what 'conventional' knowledge is for DC current flow. Is it worth changing the direction of the transducer on the sensed wire to check?

The transducer output is an active output so you'd think you'd get 4mA with no current on the sensed wire. But . . . .

1. The I/O module has the 4-20mA (-) connect to the L(-) terminal. If the 4-20mA is not an isolated output (which I doubtt given that terminals 2 & 3 are tied together on the transducer), you could have a ground loop problem between the transducer DC supply/transducer 4-20mA return and the I.O L(-).

Is there some reason you're not using the I/O modules L(+) for DC power to the transducer? The DCT100 needs 2VA or 85mA

2. The transducer is measuring DC current and the instructions are specific that the current flow must match the arrow on the device.

Is current flow (+) to (-) or (-) to (+)? Somehow, they forgot to specify and I'm old enough to remember debates about current flow, so I don't know what 'conventional' knowledge is for DC current flow. Is it worth changing the direction of the transducer on the sensed wire to check?

I previously testing the following wiring:1. The I/O module has the 4-20mA (-) connect to the L(-) terminal. If the 4-20mA is not an isolated output (which I doubtt given that terminals 2 & 3 are tied together on the transducer), you could have a ground loop problem between the transducer DC supply/transducer 4-20mA return and the I.O L(-).

Is there some reason you're not using the I/O modules L(+) for DC power to the transducer? The DCT100 needs 2VA or 85mA

+Power -> L+

-Power -> L-

+OUT -> 4-20 analog input

-OUT -> empty

This displayed "UL" (Process value too low). I then swapped the analog input to -OUT and left +OUT empty and also get UL. I've tried reversing the transducer direction without success or any change to my outputs.

Perhaps @Tom Jenkins suggestion of lowering the sensing range could help?.. But shouldn't the baseline be 4 mA with no current regardless of the sensing range.

The DCT is a four-wire device, so I would eliminate the display unit from the circuit until the DCT configuration/function is verified. You can connect your meter to the 4(+) and 3(-) terminals directly. You should measure 4mA if there is no load. If you removed the range jumper to select the 0-50A range, 10A load should give you ~7.2mA output.

danw

Lifetime Supporting Member

I agree with climtm. You need to confirm that the transducder/transmitter works on its own as a starting point.

Powering it with your DC power supply and connecting the output to nothing but a milliampmeter should tell you whether it is functional or not. You're right, even with no current on the sensing side, it should output 4mA.

Powering it with your DC power supply and connecting the output to nothing but a milliampmeter should tell you whether it is functional or not. You're right, even with no current on the sensing side, it should output 4mA.

I tested again with my multimeter with the following set up: I removed the display unit and +Power and -Power was connected to +V and -V of my 24V PSU. Red lead on MM on +Out and Black COM lead on MM on the -Out. I connected to power and confirmed it was receiving 24V, I got an output of 1.1mA... Safe to say there is an issue with the DCT?

It was a brand new unit, but I will try to get a new one to test... but now I wonder if I did damage to it any point in my testing? I at no point had an output from the DCT, so I don't think I did, but could me connecting directly to the PSU for power something that could cause damage to it over using the PLC module +24V supply?

It was a brand new unit, but I will try to get a new one to test... but now I wonder if I did damage to it any point in my testing? I at no point had an output from the DCT, so I don't think I did, but could me connecting directly to the PSU for power something that could cause damage to it over using the PLC module +24V supply?

danw

Lifetime Supporting Member

I think you got a bad one.

I finally found a DCT200-42-24-S (split core, 100A) I had purchased last year, but haven't installed yet. With power connected and no load (I don't have anything close to 100A in my office), I see 4mA on the output. As danw said, it looks like you have a bad one.

Got a new DCT and did the same testing I did above, this time I am getting 0.0-0.02mA. I have also tried using the +24V and GND from my PLC module for my + and -Power, with no output. I am using a HRP-150-24 PSU, is there some issue with the power supplies I am using or a different way I should try measuring this?I removed the display unit and +Power and -Power was connected to +V and -V of my 24V PSU. Red lead on MM on +Out and Black COM lead on MM on the -Out. I connected to power and confirmed it was receiving 24V

danw

Lifetime Supporting Member

Is the fuse in the milliampmeter blown? Have you tested the meter on a known good 4-20mA DC circuit?

The transducer uses 2 VA, which at 24Vdc is 85mA. Your power supply is 150VA (6.5A) so it should handle a 2VA load. When everything is connected, the power supply still read 24V across its terminals, right?

The split core is closed? Jaws touch each other?

range jumper removed?

You've read the troubleshooting list on the installation page (bottom of page 2)?

https://cdn.automationdirect.com/static/manuals/acuampinserts/dct_installation.pdf

The transducer uses 2 VA, which at 24Vdc is 85mA. Your power supply is 150VA (6.5A) so it should handle a 2VA load. When everything is connected, the power supply still read 24V across its terminals, right?

The split core is closed? Jaws touch each other?

range jumper removed?

You've read the troubleshooting list on the installation page (bottom of page 2)?

https://cdn.automationdirect.com/static/manuals/acuampinserts/dct_installation.pdf

OkiePC

Lifetime Supporting Member

I recommend a Fluke 789 or 707 loop calibrator for anyone who deals with 4 to 20mA signals. I use mine all the time to validate my understanding of an instrument before landing the wires. These meters have a "Measure - Loop Power" mode that lets me test two wire devices completely isolated from control panel voltages, by supplying voltage to the device while measuring the returned current.

This one tool will help you keep the magic smoke inside the instruments and has probably paid for itself many times over.

This one tool will help you keep the magic smoke inside the instruments and has probably paid for itself many times over.

Checked both mA and 10A fuses on the MM, they were good. The testing conditions are:

- fixed core

- jumper removed

- no load/wire passing through center

- 24V PS on pins 1 and 2

- terminal screwed down on pins 3 and 4

Similar Topics

I purchased a 4-20ma AC Current Transducer, it can be set to 0-100a, 0-150a, 0-200a. It is not True-RMS.

This is connected to a panel meter and I...

- Replies

- 1

- Views

- 1,486

Dear experts,

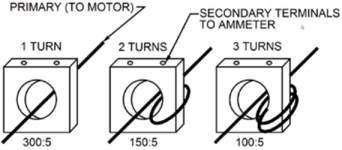

i have a CT 600/5A and analog Amps meter 0-600A @2.5Class,

1)now i want to measure the same current to changing analog meter to...

- Replies

- 1

- Views

- 2,407

My current project involves instrumentation for AC current. Input current range is 0-5 A (AC). Output of the device to be used has to be 4-20 mA...

- Replies

- 2

- Views

- 3,165

Today I was working on my project for school and we were using a power supply with 24V and we accidentally had the current at 0.9A. We heard a pop...

- Replies

- 9

- Views

- 549

HI

i have a delta VFD M-series in the manual, in order to enter the motor rated current you set the parameter P,52 =the motor rated current

my...

- Replies

- 7

- Views

- 666