udtwmc

Member

Hi,

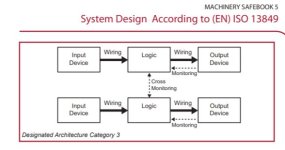

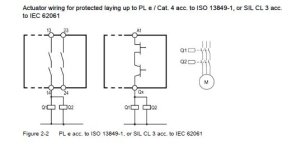

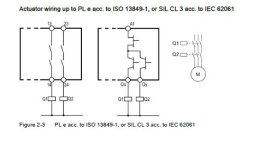

I'd like to understand the difference between the following 'functional safety' wiring methods and how they relate to the EN13849-1 'input - logic - output' block diagrams. It's the 'Output device' that i feel i'm misunderstanding ...

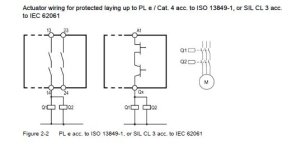

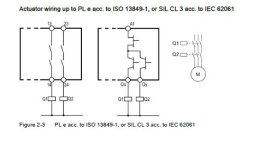

So, is the output device from the first block diagram (according to EN13849-1) referring to the power contactors Q1 and Q2 in figures 2-2 & 2-3 or is it the safety relay 'internal' pair of contacts between terminals 13 & 14?

both schematics state they meet PLe however figure 2-3 obviously looks (and is) more fault tolerant as it uses 2 contactors on 2 separate channels but i would like to save on relay outputs by energizing my Q1 & Q2 with just one output channel as in figure 2-2 ... while i have appeared to have answered my own question, i still have conflicting views from work colleagues and other publications on this matter that tend to only show Cat3/4 as using 2 separate output channels to drive 2 contactors ( btw i am monitoring Q1 and Q2 back into my safety relay)

Also, the block diagram from 13849-1 does appear to me to mean 2 separate output channels as in figure 2-3 whereas if it clearly meant the internal contacts of the safety relay that would make me feel better.

hope that makes some sense and you can shed some light on the matter!

cheers

I'd like to understand the difference between the following 'functional safety' wiring methods and how they relate to the EN13849-1 'input - logic - output' block diagrams. It's the 'Output device' that i feel i'm misunderstanding ...

So, is the output device from the first block diagram (according to EN13849-1) referring to the power contactors Q1 and Q2 in figures 2-2 & 2-3 or is it the safety relay 'internal' pair of contacts between terminals 13 & 14?

both schematics state they meet PLe however figure 2-3 obviously looks (and is) more fault tolerant as it uses 2 contactors on 2 separate channels but i would like to save on relay outputs by energizing my Q1 & Q2 with just one output channel as in figure 2-2 ... while i have appeared to have answered my own question, i still have conflicting views from work colleagues and other publications on this matter that tend to only show Cat3/4 as using 2 separate output channels to drive 2 contactors ( btw i am monitoring Q1 and Q2 back into my safety relay)

Also, the block diagram from 13849-1 does appear to me to mean 2 separate output channels as in figure 2-3 whereas if it clearly meant the internal contacts of the safety relay that would make me feel better.

hope that makes some sense and you can shed some light on the matter!

cheers