Programming PLCs is primarily about time: the repeating scan cycles and the order of evaluation of rungs+branches+instructions comprise the clock.

The question we tend to ask are what it is doing or why it is doing something, but with PLC a more interesting, useful and diagnostic question is when did it do something?

There is no "fighting" going on even if only one tag is used for all of the sums' results. Rather the value of that one tag is updated at different times during the sequential and separate-in-time evaluations of those instructions.

In most PLC programming software that has an online mode to monitor live values, the displayed values for the instruction parameters are usually loaded from the values of the tags sample at some specific time, probably at the end of the logic scan cycle.

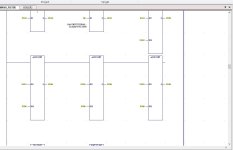

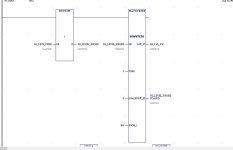

So it makes sense that, for all instances where the value of tag B2_2_LVL_SUM is displayed, the online display shows the same single final-in time value of "20000" in your 1.JPG example.

The displaying software does not care or know that the three tags around an ADD instruction were the operands to, and result from, an addition - the values of those operands and that result at the time of instruction evaluation are in the past; rather the software only knows the location of the tags on the screen and the names of the tags, and it uses those tag names to retrieve (i.e. sample at a fixed time or from a snapshot in time) the values and then write those one-time sampled values near the location of the tag.

There are some PLC programming applications (TIA Portal) that do keep track of the operands and result of an instruction from the time of its last evaluation, and ties those value to the instruction instead of to the tags. But it takes extra memory to do so, and the history of PLCs is that memory is a scarce resource, so very few applications have ever done that.