hamedkhatab

Member

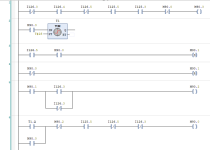

i hope you could help me to convert the network Stl to lad

it's apart from program of machine

and i try to find solution for the reason of error

AN I 126.3

A I 126.4

AN I 126.5

A I 125.5

A I 125.3

AN M 90.0

= M 90.3

A M 90.3

L S5T#2S

SD T 1

A I 126.5

A M 90.0

S M 90.1

AN M 90.0

R M 90.1

A M 90.1

A(

O I 126.3

ON I 126.3

)

= M 90.2

A(

O T 1

O M 90.0

)

AN M 90.2

A I 125.5

AN I 126.5

AN I 126.3

= M 90.0

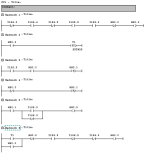

it's apart from program of machine

and i try to find solution for the reason of error

AN I 126.3

A I 126.4

AN I 126.5

A I 125.5

A I 125.3

AN M 90.0

= M 90.3

A M 90.3

L S5T#2S

SD T 1

A I 126.5

A M 90.0

S M 90.1

AN M 90.0

R M 90.1

A M 90.1

A(

O I 126.3

ON I 126.3

)

= M 90.2

A(

O T 1

O M 90.0

)

AN M 90.2

A I 125.5

AN I 126.5

AN I 126.3

= M 90.0