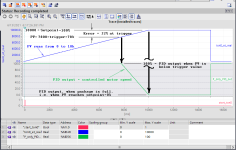

Generally speed of filling is a production must, just run at the highest speed you can until nearly full, then slow it down maybe you need say 3 speeds.

It's just a matter of trials Done this many times with liquids & solids in various ways, valves conveyors vibrators cones.

The only other things to consider is ramp down time perhaps a quick ramp down on the settings for example a VFD often will have ramp times set in seconds or part thereof, reduce the ramp down time to minimum perhaps have the final kg or lbs where you slow to a trickle plus a small in-flight value to allow for the delay before the last of the product is in the container.

It's just a matter of trials Done this many times with liquids & solids in various ways, valves conveyors vibrators cones.

The only other things to consider is ramp down time perhaps a quick ramp down on the settings for example a VFD often will have ramp times set in seconds or part thereof, reduce the ramp down time to minimum perhaps have the final kg or lbs where you slow to a trickle plus a small in-flight value to allow for the delay before the last of the product is in the container.