Ken Roach

Lifetime Supporting Member + Moderator

This feels like a simple, elementary question, but I am a Siemens novice and know there are experts here.

My S7-1500 project (TIA Portal v17) has an I/O device that uses some PLC Data Types, including one that holds Status Bits. The data type has 32 named BOOLs inside it.

I want to copy those 32 bits into a DWord type Internal Memory tag, for an HMI feature to read bit-by-bit. The HMI is actually the WinCC Unified View of Things webserver feature and I want to create a set of indicator boxes on screen so show the status of each Bit in the Status Bits tag.

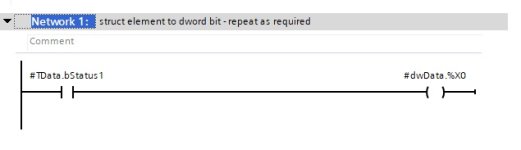

What is the correct LAD instruction that will copy the contents of a PLC Data Type tag into a DWord tag ?

My S7-1500 project (TIA Portal v17) has an I/O device that uses some PLC Data Types, including one that holds Status Bits. The data type has 32 named BOOLs inside it.

I want to copy those 32 bits into a DWord type Internal Memory tag, for an HMI feature to read bit-by-bit. The HMI is actually the WinCC Unified View of Things webserver feature and I want to create a set of indicator boxes on screen so show the status of each Bit in the Status Bits tag.

What is the correct LAD instruction that will copy the contents of a PLC Data Type tag into a DWord tag ?