Peter Nachtwey

Member

Mas01 has not been clear about that the absolute pressure is in the vessel. He has said 20 torr and too is absolute. I have quoted him above.@Peter Nachtwey why are you being such a jerk? The man says the tank is at 20 torra and he is trying to measure level of water.

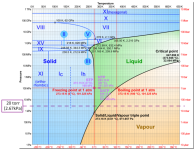

If the pressure in the is 20 torr then it is near a perfect vacuum and water will boil. If the pressure is at 740 torr then it won't boil.

NOW READ THIS TO SEE THE DEFINITION OF TORR

https://en.wikipedia.org/wiki/Torr

torr is an absolute scale, not a relative one

I have seen all sorts of screw ups.If they're designing a test system, do you really think the mechanical/chemical engineer involved doesn't know his/her steam tables?

I have not been harping on it non-stop. Stop lying. I made a post #5 and have waited 5 pages watching you guys flail and fail because the uncertainty still persist. There is a huge difference between 20 torr and 740 torr.It's worth it to bring it up, but harping on it non-stop, obviously not reading the rest of the thread, and then condescending not only OP but everyone trying to help him isn't a good look.

Being precise is important.

Torr is not relative. 20 torr is a vacuum too. See the wikipedia post.@Peter Nachtwey: if you are mocking anyone about flailing, then why are you bringing steam into this? When 20Torr was first mentioned, it was mentioned as a vacuum

Where was -20 torr relative to atmospheric mentioned?

What I saw is

Mas01 said:No, no...the absolute value is 20 Torr inside the vessel.