CLXlifestyle

Member

Yes, exactly right, my HMI is the one doing the latching. Unfortunately, I need to keep it this way. At the end of the day, the motors will be turned off, and then the next day, the first operator will come and manually turn on the motors through the HMI. They won't have the PLC logic in front of them to toggle on and off.

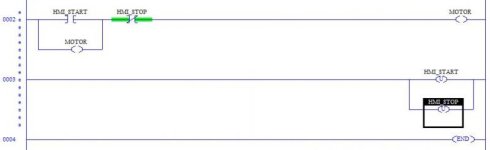

No no, what everyone is saying is to make your button momentary, so it functions like a start switch. Your PLC logic should look like this:

http://image.slidesharecdn.com/wiri...ams-and-ladder-logic-70-638.jpg?cb=1462993102

You don't need to see the logic in the PLC to make this work. They hit the button the HMI and it momentarily "blips" the start circuit, starting the motor.