prakasha

Member

Hi Guys

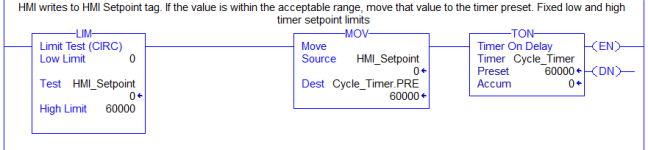

Today we went through the worst situation that PLC went to major fault Mode due to Trap by one of the Timer with -ve Value Moved into Preset.

What is the best way to prevent or avoid this kind of acts while implement or developing the program. I know there is option Fault Handler Program can be written but is it possible to prevent plc being trapped by loop by writing the program in fault handler. How can we avoid this kind errors while developing the program. Plz advice me to come out from this

Today we went through the worst situation that PLC went to major fault Mode due to Trap by one of the Timer with -ve Value Moved into Preset.

What is the best way to prevent or avoid this kind of acts while implement or developing the program. I know there is option Fault Handler Program can be written but is it possible to prevent plc being trapped by loop by writing the program in fault handler. How can we avoid this kind errors while developing the program. Plz advice me to come out from this

Last edited: