dalporto

Lifetime Supporting Member

Hi all.

I'm trying to set up communication between a 1756-L72 (EN2TR) and a 1756-L82 (CPU port) using produced / consumed tags.

From the L72 config, I was able to add the L82 in the tree under the EN2TR with the module discovery, and the data exchange is working when I produce a value in the L82 and read it in the L72.

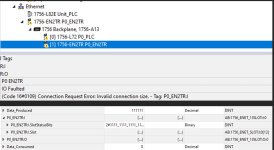

I then tried to "add/discover" the L72 EN2TR to the L82 Ethernet tree, and it's not discovered. So I manually added it (EN2TR + L72, and it's not working.

It's creating (only in L82) two new structures (In/Out) that it didn't on L72. Looks like the data Type is refering to an ENET module, which is weird.

You can see the fault code on the screen shot.

Any clue anyone?

I'm trying to set up communication between a 1756-L72 (EN2TR) and a 1756-L82 (CPU port) using produced / consumed tags.

From the L72 config, I was able to add the L82 in the tree under the EN2TR with the module discovery, and the data exchange is working when I produce a value in the L82 and read it in the L72.

I then tried to "add/discover" the L72 EN2TR to the L82 Ethernet tree, and it's not discovered. So I manually added it (EN2TR + L72, and it's not working.

It's creating (only in L82) two new structures (In/Out) that it didn't on L72. Looks like the data Type is refering to an ENET module, which is weird.

You can see the fault code on the screen shot.

Any clue anyone?