Mickey

Lifetime Supporting Member

Thank Mickey! Now I'm getting an idea of how split-range control is implemented.. I'm trying to write my own program and will post it once I finished it. Also I was unable to open the TwoControl_split.zip file. Can you please post .pdf version of the program.

Thank you,

Ding

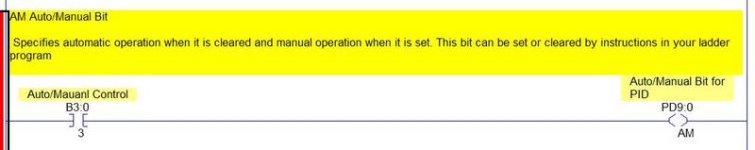

Sure it's only two rungs.