All

Using a MicroLogix 1400. Not a huge program doing an auto stop function

based on a calculated roll diameter Using encoder feedback for unwind rpm

and machine speed in FPM. There is a small Panelview for operator inputs.

They can enter the accel decel speeds for ramps in FPM/S. I calculate a increment value and do a subtract of that value from the current setpoint.

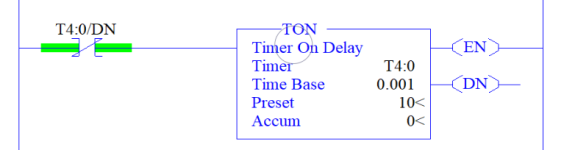

every 10 milliseconds from the done bit of a free running timer. it has a time base of .001 and a preset of 10. My done bit is only triggering the sub block about half of what it should in a 10 second period during testing.

processor scan time highest was 6.3 ms.

Is the MicroLogix not capable of this?

Best Regards

Using a MicroLogix 1400. Not a huge program doing an auto stop function

based on a calculated roll diameter Using encoder feedback for unwind rpm

and machine speed in FPM. There is a small Panelview for operator inputs.

They can enter the accel decel speeds for ramps in FPM/S. I calculate a increment value and do a subtract of that value from the current setpoint.

every 10 milliseconds from the done bit of a free running timer. it has a time base of .001 and a preset of 10. My done bit is only triggering the sub block about half of what it should in a 10 second period during testing.

processor scan time highest was 6.3 ms.

Is the MicroLogix not capable of this?

Best Regards