Lesson Motor 230VAC-1.2A-1700RPM-62.5PF

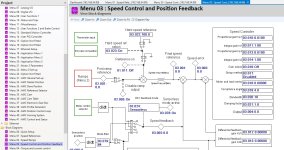

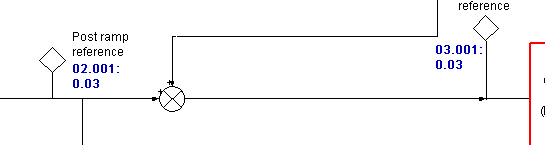

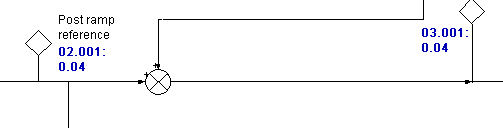

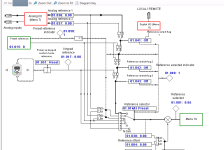

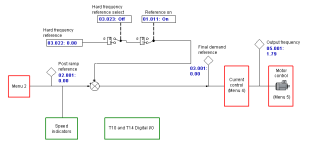

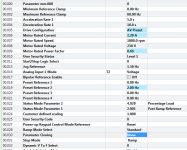

I am having trouble understanding this. My motor rotates at 0vdc reference with the run forward command. Even in pad. I can correct this by increasing the RPMs to 1800. it took me quite a bit of time to track down a remedy but i do not know what the relationship would be to cause this.Nidec service is unavailable right now so i was hoping for some explanation or advice on something I am missing. Thanks for any consideration.

I am having trouble understanding this. My motor rotates at 0vdc reference with the run forward command. Even in pad. I can correct this by increasing the RPMs to 1800. it took me quite a bit of time to track down a remedy but i do not know what the relationship would be to cause this.Nidec service is unavailable right now so i was hoping for some explanation or advice on something I am missing. Thanks for any consideration.