PluemandNicha

Member

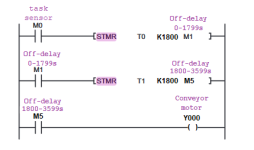

"Hello, I am a beginner learning about PLC. Could you please give me some advice? I want to write PLC instructions as follows:

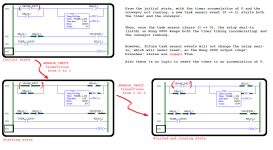

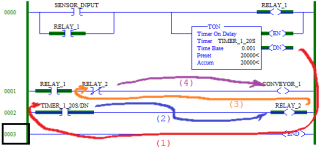

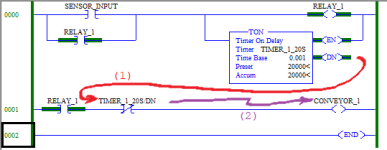

When the sensor detects a task, turn the sensor on and command the conveyor to rotate.

At the same time, the sensor should start a 1-hour timer.

If 1 hour passes without any new tasks coming in, the conveyor should stop rotating. However, if a new task comes in, the timer instruction should be reset, and the conveyor should continue rotating."

pic is here https://twitter.com/ntmeannicetry/status/1659564025917898754?s=46&t=qzI7fFoAR7iJU9DBxOMm3A

When the sensor detects a task, turn the sensor on and command the conveyor to rotate.

At the same time, the sensor should start a 1-hour timer.

If 1 hour passes without any new tasks coming in, the conveyor should stop rotating. However, if a new task comes in, the timer instruction should be reset, and the conveyor should continue rotating."

pic is here https://twitter.com/ntmeannicetry/status/1659564025917898754?s=46&t=qzI7fFoAR7iJU9DBxOMm3A