Hello guys,

I have problems with the Porfibus communication to my regulator Siemens Sipart DR 21and my PLC rockwell 1756-L161.

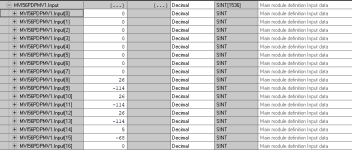

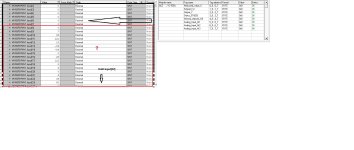

So, for the communication between the 2 devices i have on the plc a card MVI56-PDPMV1 made by prosoft, and i have a card 6DR2803-8P made by Siemens on my regulator.

The concern is that once the communication is established, I don't know how to send information from my regulator to my PLC, nothing is specified in the documentation and no approach or software is recommended.

I am in a stalemate.

If anyone among you has already done a transfer of data via Porfibus to a regulator of this type I would be grateful for his help.

Thank you all and have a nice day.

I have problems with the Porfibus communication to my regulator Siemens Sipart DR 21and my PLC rockwell 1756-L161.

So, for the communication between the 2 devices i have on the plc a card MVI56-PDPMV1 made by prosoft, and i have a card 6DR2803-8P made by Siemens on my regulator.

The concern is that once the communication is established, I don't know how to send information from my regulator to my PLC, nothing is specified in the documentation and no approach or software is recommended.

I am in a stalemate.

If anyone among you has already done a transfer of data via Porfibus to a regulator of this type I would be grateful for his help.

Thank you all and have a nice day.