kemosabian

Member

Hi Guys,

I am a new member and this is my first post!

I have a little PLC experience but it is mostly with siemens logo and using ladder logic. I have had training on Beckhoff and I've got a bit of experience in Python, C, C++ and I've done some basic Arduino programming.

I've recently started a new project to upgrade an existing control system by adding Modbus devices, the original PLC was a Rievtech micro PLC. The new modbus registers provided the data as 32bit floats and from a cost, size, performance point of view the Micro820 looked like the best option. However, I have two problems:

1) I have went in a bit gun ho and I think I've changed my IP address setting so I cant communicate with the PLC. To make matters worse I've tried folloing advice on here and youtube to update the firmware and to connect over RS232 and neither has worked. But I will persevere to re-establish comms!

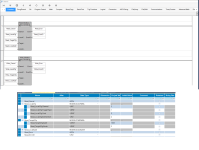

2) I have managed to poll the device (set to address 2) using the built in RS485 connnection and the device recognises that it is being polled (and is presumably responding). The Micro820 does not receive any response though and doesn't recognise a time-out either. I thought perhaps the issue was "message turnaround delay" of the slave device noted in the manual (see attachment) so I tried adjusting the Micro820 protocol control to compensate for this to no avail.

Am I barking up the wrong tree? HELP!

I am a new member and this is my first post!

I have a little PLC experience but it is mostly with siemens logo and using ladder logic. I have had training on Beckhoff and I've got a bit of experience in Python, C, C++ and I've done some basic Arduino programming.

I've recently started a new project to upgrade an existing control system by adding Modbus devices, the original PLC was a Rievtech micro PLC. The new modbus registers provided the data as 32bit floats and from a cost, size, performance point of view the Micro820 looked like the best option. However, I have two problems:

1) I have went in a bit gun ho and I think I've changed my IP address setting so I cant communicate with the PLC. To make matters worse I've tried folloing advice on here and youtube to update the firmware and to connect over RS232 and neither has worked. But I will persevere to re-establish comms!

2) I have managed to poll the device (set to address 2) using the built in RS485 connnection and the device recognises that it is being polled (and is presumably responding). The Micro820 does not receive any response though and doesn't recognise a time-out either. I thought perhaps the issue was "message turnaround delay" of the slave device noted in the manual (see attachment) so I tried adjusting the Micro820 protocol control to compensate for this to no avail.

Am I barking up the wrong tree? HELP!