BiteBytesButes

Member

Hi...

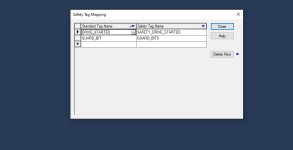

I have what is so-called "Limit Values" placed in the Safety PLC. These values were written in REAL safety tags format.

It turns out that, after the Safety function on PLC be "closed" (Safety blocked) I cannot update them via SCADA writing.

I understand why this isn't possible, it is the Safety function itself does not allow it.

Is there any way to achieve this? Be able to update these tags via SCADA?

" from Rockwell GuardLogix manual:

The safety-lock feature applies only to safety components, such as the safety task, safety programs, safety routines, safety tags, safety Add-On Instructions, safety I/O, and safety

signature."

Thank you!

3B

I have what is so-called "Limit Values" placed in the Safety PLC. These values were written in REAL safety tags format.

It turns out that, after the Safety function on PLC be "closed" (Safety blocked) I cannot update them via SCADA writing.

I understand why this isn't possible, it is the Safety function itself does not allow it.

Is there any way to achieve this? Be able to update these tags via SCADA?

" from Rockwell GuardLogix manual:

The safety-lock feature applies only to safety components, such as the safety task, safety programs, safety routines, safety tags, safety Add-On Instructions, safety I/O, and safety

signature."

Thank you!

3B