joshwgreen1982

Member

So I very much new to doing ladder coding

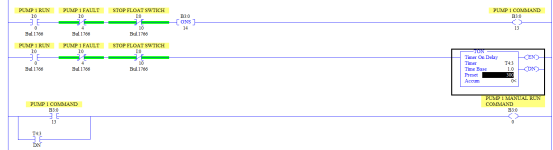

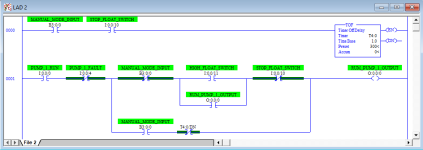

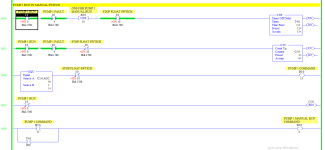

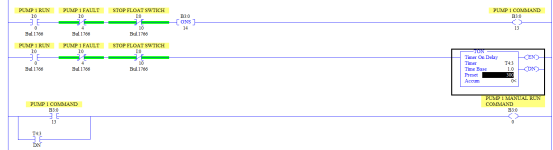

I have a pump with a Stop float switch that stops the pump when a sump is low. I want my manual run mode to start the pump immediately when run manual mode is activated and the stop float switch is not active. When the stop float is activated the pump will stop. When the float is not active again the pump will not restart for 5 mins.

I have a picture of my code but the TON runs first instead of the pump starting immediately. I thought a ONS would work but I guess not.

Code attached.

I have a pump with a Stop float switch that stops the pump when a sump is low. I want my manual run mode to start the pump immediately when run manual mode is activated and the stop float switch is not active. When the stop float is activated the pump will stop. When the float is not active again the pump will not restart for 5 mins.

I have a picture of my code but the TON runs first instead of the pump starting immediately. I thought a ONS would work but I guess not.

Code attached.