tim_callinan

Member

Hi All,

I have a couple of questions and would appreciate any help from you guys. I've included my rslogix code and a youtube video of our PLC trainer. Im going to be teaching a class with some PLCs in it this fall and am trying to study up on PLCs as much as possible.

My first question is on PLC structure or programming style. I wrote the ladder logic in a very sequential way - each rung has a progress or completion bit that gets latched once the line has completed.- and then it moves onto the next line. (If you have a look in the code it should make sense.) Is this the best way or method to program the system in the video??

http://www.youtube.com/watch?v=Ds1nYcDOR18

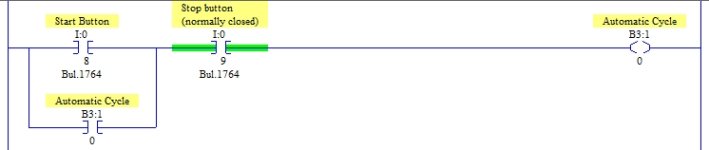

My second question is the entire sequence starts once the 'start button' is pressed. I need this system to start and then cycle unless the stop button is pressed.

Hopefully I've made some sense. Any help would be appreciated.

Thanks,

Tim

I have a couple of questions and would appreciate any help from you guys. I've included my rslogix code and a youtube video of our PLC trainer. Im going to be teaching a class with some PLCs in it this fall and am trying to study up on PLCs as much as possible.

My first question is on PLC structure or programming style. I wrote the ladder logic in a very sequential way - each rung has a progress or completion bit that gets latched once the line has completed.- and then it moves onto the next line. (If you have a look in the code it should make sense.) Is this the best way or method to program the system in the video??

http://www.youtube.com/watch?v=Ds1nYcDOR18

My second question is the entire sequence starts once the 'start button' is pressed. I need this system to start and then cycle unless the stop button is pressed.

Hopefully I've made some sense. Any help would be appreciated.

Thanks,

Tim