Dumbplcguy

Member

Hi guys,

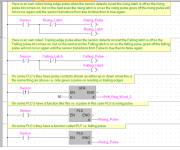

I am pretty new when it comes to programming. I am working with CX-Programmer and I am having a problem where I have a sensor on my machine and it is supposed to detect green tape on the material and then cut it off. At first the green tape would not make it to the cutter and it would mostly be material instead of the green tape. Then I added a shift register to track the positioning. Now it cuts up until the front edge of the green tape, feeds through a little bit but it cuts into the green tape when it is supposed to cut into the trailing edge of it. I tried to adjust the shift register but it caused the cutter to cut into the material too far ahead of the green tape. Right now in the shift register I have 441-448. How do I get it to cut into the front leading edge of the green tape, have it feed all the way through, and cut into the trailing edge of it?

I also want to note that there is a 100 ms debounce timer that is at #40 when the green tape is detected.

Sorry if this is all over the place as I am new and explaining PLC related problems are also new to me.

Thanks in advance.

I am pretty new when it comes to programming. I am working with CX-Programmer and I am having a problem where I have a sensor on my machine and it is supposed to detect green tape on the material and then cut it off. At first the green tape would not make it to the cutter and it would mostly be material instead of the green tape. Then I added a shift register to track the positioning. Now it cuts up until the front edge of the green tape, feeds through a little bit but it cuts into the green tape when it is supposed to cut into the trailing edge of it. I tried to adjust the shift register but it caused the cutter to cut into the material too far ahead of the green tape. Right now in the shift register I have 441-448. How do I get it to cut into the front leading edge of the green tape, have it feed all the way through, and cut into the trailing edge of it?

I also want to note that there is a 100 ms debounce timer that is at #40 when the green tape is detected.

Sorry if this is all over the place as I am new and explaining PLC related problems are also new to me.

Thanks in advance.