New to these forums, I tried searching for this but couldn't find it.

I'm finding this situation frequently in this program I'm converting. As far as I understand, any flag bit above 200 is considered a "scratch flag" which to my understanding is used like a temporary memory bit or local tag.

I'm trying to understand the reasoning behind it's use here. My best guess is the intent was to bypass the timers and Q70.2

If anybody has more info on how these scratch flags were used (in general) that would be helpful. It's use looks redundant to me in most cases. Thanks.

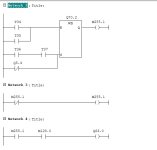

A(

O T 34

O T 35

R Q 70.2

A T 36

A T 37

ON Q 5.4

S Q 70.2

A Q 70.2

)

= F 255.1

AN F 255.1

= F 255.1

A F 255.1

A F 128.0

= Q 66.0

I'm finding this situation frequently in this program I'm converting. As far as I understand, any flag bit above 200 is considered a "scratch flag" which to my understanding is used like a temporary memory bit or local tag.

I'm trying to understand the reasoning behind it's use here. My best guess is the intent was to bypass the timers and Q70.2

If anybody has more info on how these scratch flags were used (in general) that would be helpful. It's use looks redundant to me in most cases. Thanks.

A(

O T 34

O T 35

R Q 70.2

A T 36

A T 37

ON Q 5.4

S Q 70.2

A Q 70.2

)

= F 255.1

AN F 255.1

= F 255.1

A F 255.1

A F 128.0

= Q 66.0