mA for loop is OK but channel give me -1 on scada

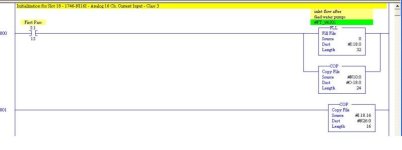

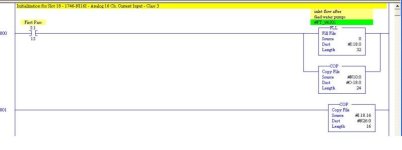

Where is this "-1 on scada"? If you are talking about your Rung 14, then when N26:5/15 is OFF or 0, then a -1 will be moved to F8:5. Now what controls N26:5/15? Are these 3 bits N26:5/13, /14, and /15 supposed to be the configuration error bits for your analog input channel, or what? Why is your program moving a -1 to F8:5 if you want F8:5 instead to be your analog input? Is this a error-handling routine? If so, you may not need it at all because your configuration in N10:0 is for a Class 3 configuration, not a Class 1.

Bits 1 and 0 are only used in Class 1 mode. If these bits are set while

in Class 3 mode, a configuration error is set in the status word (bits 15, 14, and 13 set to 0, 1, and 1). The use of these bits is not necessary in Class 3 because Class 3 allows for data transfer of a 32-word block.

THESE BITS 13, 14, & 15 of the analog configuration word SHOULD BE SET TO OTHER THAN 0,0,0 ONLY WHEN USING THE OLD CLASS 1 CONFIGURATION. If using the newer Class 3, then bits 13, 14, & 15 should each always be 0!

Note that your Rung 14 is doing the -1 move when there is a 0 in any bit 13, 14, or 15. For a Class 3 setup (which I think you have as shown by N10:0) there should ALWAYS be a 0 in all 3 positions!

To help you more, we need to see the rungs that sets the values of N26:5/13, /14, and /15, and know what these 3 bits are really.