sachin10

Member

hello All,

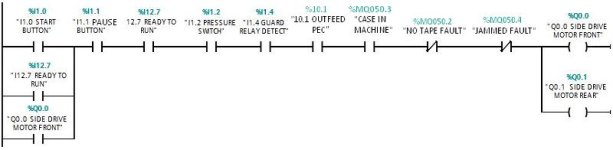

i have some requirements from customer that when they give us a signal then my machine motor starts and when signal goes low motor should stop.

if you look at the prog i have ready to run from customer when i press start button and i have high signal then motor starts.

and in network 2 when signal goes law at that time box is not in machine and outfeed sensor is clear then motor stops.

now when i get high signal again it doesnot start i have to press start button manually to run .

is there any way i can change the programme to start and stop from customer signal.

please advice.

thanks friends

i have some requirements from customer that when they give us a signal then my machine motor starts and when signal goes low motor should stop.

if you look at the prog i have ready to run from customer when i press start button and i have high signal then motor starts.

and in network 2 when signal goes law at that time box is not in machine and outfeed sensor is clear then motor stops.

now when i get high signal again it doesnot start i have to press start button manually to run .

is there any way i can change the programme to start and stop from customer signal.

please advice.

thanks friends