Hello I am new to setting up a flow meter totalizer in ladder logic.I know using pulse to configure gallons total would be best, but currently 4-20 ma is what i have to work with.

I am using studio 5000 software and control logix hardware.

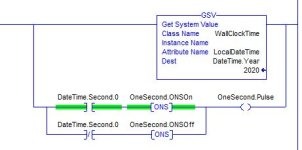

I am currently using the compute instruction with this formula below to get my total:

(mag register/60+HMI total) ex. 250gpm/60+600 gallons this is pulsed every 1000 ms by a timer dn. bit. and the accumulation is showed on the HMI screen.

Are there any AOP instructions or a better way to create a totlizer using ladder logic.

The higher my gallon set point is the more skewed my totals become. Any help would be much appreciated. I have looked through the threads and found some good information , but some of it is over m head at the moment. Thank you

I am using studio 5000 software and control logix hardware.

I am currently using the compute instruction with this formula below to get my total:

(mag register/60+HMI total) ex. 250gpm/60+600 gallons this is pulsed every 1000 ms by a timer dn. bit. and the accumulation is showed on the HMI screen.

Are there any AOP instructions or a better way to create a totlizer using ladder logic.

The higher my gallon set point is the more skewed my totals become. Any help would be much appreciated. I have looked through the threads and found some good information , but some of it is over m head at the moment. Thank you