Hello

Long time lurker. I am flailing around trying to figure out how to implement MODBUS TCP on a W2000 IPC that controls one of my company's grinder. I am lucky enough that I have a spare IPC (k550spare) to test and learn MODBUS TCP. I am just not understanding some very very very basic items about MODBUS TCP and TwinCAT. This is the only application in my plant that has TwinCAT,and the only application that uses MODBUS.

I do have the TwinCAT MODBUS TCP Server Configuration software installed and running on the same k550spare IPC.

I am trying to communication to three different devices via TCP. One is Alta Vibration IPC, second is Ignition HMI 8.x, and the third is IBA Data Recorder. I can test the Ignition HMI and the IBA MODBUS TCP connections. I know that I have some level of communication happening from k550spare to Ignition and IBA. Ignition states I do have a connection status, but Ignition is stating there are communication errors. IBA states the same condition. I can see the error counter climbing. I am using k550spare as the source of the data, Alta, Ignition, and IBA will only read values sourced from k550spare.

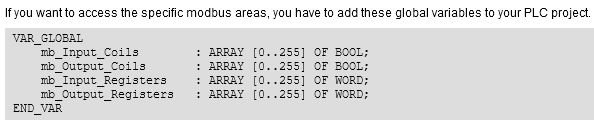

A question on screenshot attachment k550spare MODBUS TCP Server Question popup.gif; is the IP Address & Port entered here only the "Server IP & Port"? OR do I build a *.xml file that contains the addresses of all items on the MODBUS TCP? Second question on the screenshot; Does the *.xml configuration file contain ALL of the MODBUS TCP Variables? Is the MODBUS Address structure and memory map separate from k550spare?

I believe Alta, Ignition, and IBA are clients and are setup this way. I was thinking k550spare was the Server, but now I think k550spare is a client as well.

Any help is appreciated. I have had no luck using Beckhoff's website. I have been able to glean some info from other websites and manuals.

Long time lurker. I am flailing around trying to figure out how to implement MODBUS TCP on a W2000 IPC that controls one of my company's grinder. I am lucky enough that I have a spare IPC (k550spare) to test and learn MODBUS TCP. I am just not understanding some very very very basic items about MODBUS TCP and TwinCAT. This is the only application in my plant that has TwinCAT,and the only application that uses MODBUS.

I do have the TwinCAT MODBUS TCP Server Configuration software installed and running on the same k550spare IPC.

I am trying to communication to three different devices via TCP. One is Alta Vibration IPC, second is Ignition HMI 8.x, and the third is IBA Data Recorder. I can test the Ignition HMI and the IBA MODBUS TCP connections. I know that I have some level of communication happening from k550spare to Ignition and IBA. Ignition states I do have a connection status, but Ignition is stating there are communication errors. IBA states the same condition. I can see the error counter climbing. I am using k550spare as the source of the data, Alta, Ignition, and IBA will only read values sourced from k550spare.

A question on screenshot attachment k550spare MODBUS TCP Server Question popup.gif; is the IP Address & Port entered here only the "Server IP & Port"? OR do I build a *.xml file that contains the addresses of all items on the MODBUS TCP? Second question on the screenshot; Does the *.xml configuration file contain ALL of the MODBUS TCP Variables? Is the MODBUS Address structure and memory map separate from k550spare?

I believe Alta, Ignition, and IBA are clients and are setup this way. I was thinking k550spare was the Server, but now I think k550spare is a client as well.

Any help is appreciated. I have had no luck using Beckhoff's website. I have been able to glean some info from other websites and manuals.