cleansc

Member

Disclaimer: I am more of a layman and not an automation expert. The business I own has some machinery controlled by a PLC and we're having a problem so I wanted to seek some advice here for direction.

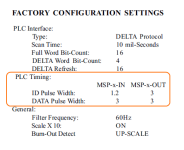

We have a problem interfacing thermcouples to the digital inputs of a PLC. The machines we are running are controlled by an Allen-Bradley (Rockwell) Micrologix 1000 1761-L16-BWA. This PLC does not have analog input capability, only digital. We have two J-Type thermocouple signals we need to feed into the PLC. This machine had been accomplishing this by way of Sensorpulse MSP-TC-IN modules (photo). These modules handle signal conditioning and A/D conversion all in one compact module. Over a single-wire to the PLC, they provide a 16-bit input, the interpretation of which is enabled by customized logic code from Sensorpulse coded into the PLC program. This appears to have been an elegant and relatively inexpensive solution. However, these modules are long obsolete and the ones we have are beginning to fail. Sensorpulse also made a multichannel card which we have on another machine and it working perfectly (until it dies...).

So the question is this:

What is the most efficient and/or economical way to get two thermocouple inputs isolated, linearized, converted to digital and intelligbly inputted into this PLC? I assume that some revision of the logic program would be required as well and would this code come off the shelf with the module? In this case, the PLC and I/O cards are housed in a small explosion proof enclosure on board the machine, so form factor is an issue as well. It may come to getting a local automation tech to come in and customize a new solution, but I'm not sure how many arms and legs that might cost us. I at least want to be aware of the options out there.

Thanks!

We have a problem interfacing thermcouples to the digital inputs of a PLC. The machines we are running are controlled by an Allen-Bradley (Rockwell) Micrologix 1000 1761-L16-BWA. This PLC does not have analog input capability, only digital. We have two J-Type thermocouple signals we need to feed into the PLC. This machine had been accomplishing this by way of Sensorpulse MSP-TC-IN modules (photo). These modules handle signal conditioning and A/D conversion all in one compact module. Over a single-wire to the PLC, they provide a 16-bit input, the interpretation of which is enabled by customized logic code from Sensorpulse coded into the PLC program. This appears to have been an elegant and relatively inexpensive solution. However, these modules are long obsolete and the ones we have are beginning to fail. Sensorpulse also made a multichannel card which we have on another machine and it working perfectly (until it dies...).

So the question is this:

What is the most efficient and/or economical way to get two thermocouple inputs isolated, linearized, converted to digital and intelligbly inputted into this PLC? I assume that some revision of the logic program would be required as well and would this code come off the shelf with the module? In this case, the PLC and I/O cards are housed in a small explosion proof enclosure on board the machine, so form factor is an issue as well. It may come to getting a local automation tech to come in and customize a new solution, but I'm not sure how many arms and legs that might cost us. I at least want to be aware of the options out there.

Thanks!

Last edited: