jrowe4

Member

Hello All! I have a PLC5 which is controlling a cocurrent drying process through a rotary kiln. I believe the control stategy of using an outlet to inlet air temperature ratio to control finished product temperature is a little strange. I would like to first try to explain the operation of the control strategy, then ask my question. Thanks before hand for taking the time out to read and offer any adivce!

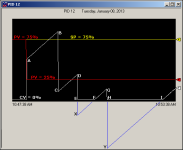

We have two seperate PD PID loops which control the inlet air and outlet air. The only interaction between the two loops is a comparison of their CV which adjusts a gas valve.

Loop 1 Outlet Air - PV: Outlet air, SP: operator command, CV:Holds in an integer register for comparison

Loop 2 Inlet Air - PV: Inlet air, SP: operator command, CV:Holds in an integer register for comparison

-If the CV of the outlet air loop is <= the inlet air loop CV (meaning that the inlet air pv is farther away from its sp than the outlet air is) we begin to open the valve.

-Secondly, if the CV of the outlet air loop is > the inlet air loop CV (meaning that the inlet air pv is closer to its sp than the outlet air is) then close the valve.

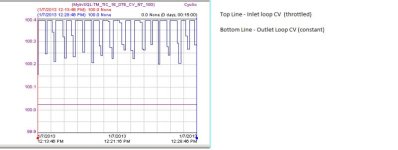

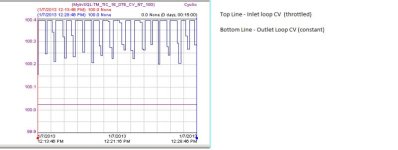

The problem is as follows. Due to the control strategy (and possibly mechanical/chemical process problems) the air out PID does not reach SP ( error is always >= 100 refer to condition 1) so we begin to open the gas valve. However, the inlet air error reduces so fast( inlet air temp rises fast <= 30 secs; refer to condition 2) that we then need to close the gas valve. Once the inlet air error becomes large again (inlet air temp drops fast <= 30 secs) we start to open the valve. Bassicly this is a vicious cycle of on off control where the outlet air very very slowly tries to get to SP and the inlet air constantly is throttled. The material temperature is usually far from its SP (about 10 deg c) and the PV inches very slowly towards SP (Not sure if we even ever get to SP)

I took a look at the PID configs for the loops and noticed something very strange in the inlet temperature control PID which I just cant wrap my head around. There is an output bias % value of -425.0277. What in the world does this mean? Does it mean that we apply -425.0277% to the output term? I tried removing the bias but then the inlet loop PV started going well beyond its SP as oppsed to before where as soon as it got to SP the valve would close. I didn't want the process PV to hit the hi hi limit so I put the bias back in.

So my question is this. Why would such a negative bias be included in the loop? How is the bias affecting the process? I've asked a couple people here and they do not seem to know the answer. There was a lot of legacy knowledge lost from the plant and I'm fresh out of college so I am lacking in the process control knowledge area . I attached the program file as well as some graphs to better explain what is going on. If anyone can offer any words of wisdom I would highly appreciate it. Thank you so much for taking the time out to hear me ramble on this!

. I attached the program file as well as some graphs to better explain what is going on. If anyone can offer any words of wisdom I would highly appreciate it. Thank you so much for taking the time out to hear me ramble on this!

We have two seperate PD PID loops which control the inlet air and outlet air. The only interaction between the two loops is a comparison of their CV which adjusts a gas valve.

Loop 1 Outlet Air - PV: Outlet air, SP: operator command, CV:Holds in an integer register for comparison

Loop 2 Inlet Air - PV: Inlet air, SP: operator command, CV:Holds in an integer register for comparison

-If the CV of the outlet air loop is <= the inlet air loop CV (meaning that the inlet air pv is farther away from its sp than the outlet air is) we begin to open the valve.

-Secondly, if the CV of the outlet air loop is > the inlet air loop CV (meaning that the inlet air pv is closer to its sp than the outlet air is) then close the valve.

The problem is as follows. Due to the control strategy (and possibly mechanical/chemical process problems) the air out PID does not reach SP ( error is always >= 100 refer to condition 1) so we begin to open the gas valve. However, the inlet air error reduces so fast( inlet air temp rises fast <= 30 secs; refer to condition 2) that we then need to close the gas valve. Once the inlet air error becomes large again (inlet air temp drops fast <= 30 secs) we start to open the valve. Bassicly this is a vicious cycle of on off control where the outlet air very very slowly tries to get to SP and the inlet air constantly is throttled. The material temperature is usually far from its SP (about 10 deg c) and the PV inches very slowly towards SP (Not sure if we even ever get to SP)

I took a look at the PID configs for the loops and noticed something very strange in the inlet temperature control PID which I just cant wrap my head around. There is an output bias % value of -425.0277. What in the world does this mean? Does it mean that we apply -425.0277% to the output term? I tried removing the bias but then the inlet loop PV started going well beyond its SP as oppsed to before where as soon as it got to SP the valve would close. I didn't want the process PV to hit the hi hi limit so I put the bias back in.

So my question is this. Why would such a negative bias be included in the loop? How is the bias affecting the process? I've asked a couple people here and they do not seem to know the answer. There was a lot of legacy knowledge lost from the plant and I'm fresh out of college so I am lacking in the process control knowledge area

Attachments

Last edited: