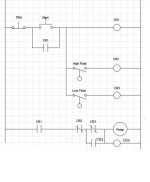

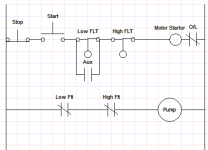

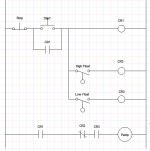

Another Electrician was trying to come up with the controls for a 2 level pump Non PLC relay controls with floats.

He wants to have a tank with 100 gals minimum, and have it stop pumping liquid in after the tank reaches 450 gals.

I tried to draw it up, but I'm stuck on how can I keep the low level pump from cycling, after the high level stops it ? Is this right ?

He wants to have a tank with 100 gals minimum, and have it stop pumping liquid in after the tank reaches 450 gals.

I tried to draw it up, but I'm stuck on how can I keep the low level pump from cycling, after the high level stops it ? Is this right ?