Hi,

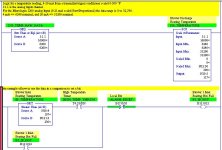

I have an application calling for use of AI pressure transmitter inputs, (4-20ma) signal, to monitor pressure and then convert that current value to AO, current output, to control motor speed operation to a VSD.

Also, I need to send an alarm to a panelview if pressure is too high, and shut off the motor.

I'm not sure how to "collect" the current signal in the ladder logic program, then convert it and compare it to a preset limit for alarm situations. This alarm is then sent to a panelview 300.

I have an application calling for use of AI pressure transmitter inputs, (4-20ma) signal, to monitor pressure and then convert that current value to AO, current output, to control motor speed operation to a VSD.

Also, I need to send an alarm to a panelview if pressure is too high, and shut off the motor.

I'm not sure how to "collect" the current signal in the ladder logic program, then convert it and compare it to a preset limit for alarm situations. This alarm is then sent to a panelview 300.