blackbird307

Member

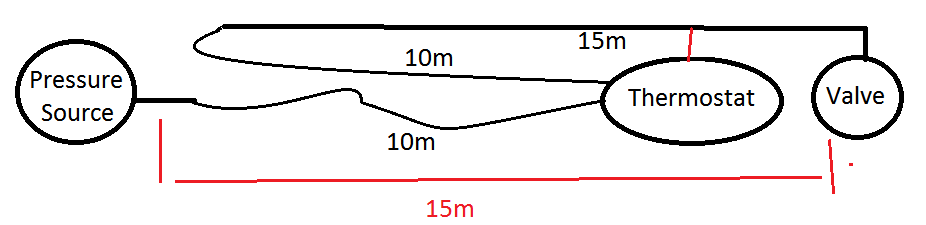

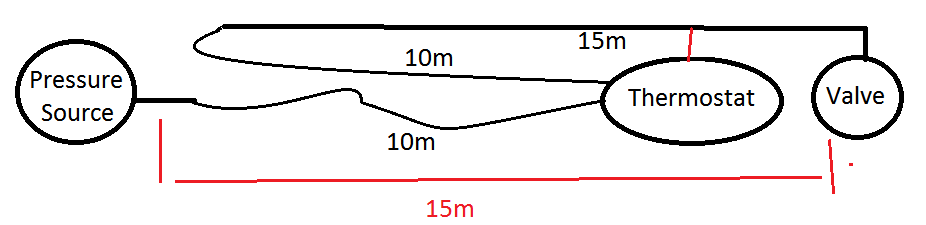

I have a pneumatic pressure source which goes to a pneumatic thermostat which opens up to source a air to open pneumatic valve at a certain temperature. The pressure at the source is a large hiss, by the time I get to the valve, it's just a draft, maybe 1/3-1/2 of source pressure.

The line is a 1/4in plastic tube which extends 10 meters to the thermostat from the source, then back to the source (10 meters) which connects to a 5/32 copper tube going to the valve (15 meters). So in total the valve is 35 meters in tube away from the pressure source. Will this length cause significant pressure drop? See illustration.

I am afraid there will not be enough pressure to close the valve. I was not able to detect any air leaks in the tube.

If I cut the copper tube and connect it closer to the stat, will I be able to solve my problem? See Red. We originally did not do this in order to leave the copper tubing intact. If however, we have to, we will cut it so we can eliminate the extra distance.

The line is a 1/4in plastic tube which extends 10 meters to the thermostat from the source, then back to the source (10 meters) which connects to a 5/32 copper tube going to the valve (15 meters). So in total the valve is 35 meters in tube away from the pressure source. Will this length cause significant pressure drop? See illustration.

I am afraid there will not be enough pressure to close the valve. I was not able to detect any air leaks in the tube.

If I cut the copper tube and connect it closer to the stat, will I be able to solve my problem? See Red. We originally did not do this in order to leave the copper tubing intact. If however, we have to, we will cut it so we can eliminate the extra distance.