kamenges

Member

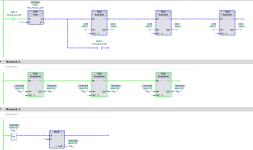

Originally posted by L D[AR2,P#0.0]:

Back to the ladder, the stuff on the left of the coil is evaluated first so it is showing correctly.

So your assertion is the OP just happened to catch that first screen shot on the scan that M202.0 went high due to the top branch? Because on the next scan M202.0 would be true heading into the rung and the contact would match the output status.

Keith