I am running out of ideas for this problem I have on one of our machines.

In advance I want to say there are no MCR's or doubled outputs in some other subroutines.

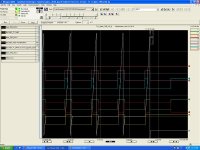

I will also upload the trend screenshot and logic screenshot.

Trend was set for max possible resolution, 1ms.

The white line is degrees (coming from encoder) - machine makes full revolution - 0-360 degrees, and home position is around 68.

Problem only happens when encoder makes jump from 359 to 0 degrees. It doesn't happen always.

What I don't understand is the actual logic behavior. You can see that my output 010.6 is a green line and it is being energized when 014.5 goes high (cyan) and then it will latch itself together with CAM2 (yellow line). What I don't understand is why it drops out ?

I can see that yellow is staying high (and this is basically position of the encoder - everything thats not in between 60-75 degrees). and since it's latching itself in, it should not go LOW.

Red output is just an upper rung and it goes high when green goes low. The pink one is the actual start/stop of the VFD that runs our transfer table.

I makes me go crazy, since I have no other ideas of what's goin on here.

Thanks to everyone,

In advance I want to say there are no MCR's or doubled outputs in some other subroutines.

I will also upload the trend screenshot and logic screenshot.

Trend was set for max possible resolution, 1ms.

The white line is degrees (coming from encoder) - machine makes full revolution - 0-360 degrees, and home position is around 68.

Problem only happens when encoder makes jump from 359 to 0 degrees. It doesn't happen always.

What I don't understand is the actual logic behavior. You can see that my output 010.6 is a green line and it is being energized when 014.5 goes high (cyan) and then it will latch itself together with CAM2 (yellow line). What I don't understand is why it drops out ?

I can see that yellow is staying high (and this is basically position of the encoder - everything thats not in between 60-75 degrees). and since it's latching itself in, it should not go LOW.

Red output is just an upper rung and it goes high when green goes low. The pink one is the actual start/stop of the VFD that runs our transfer table.

I makes me go crazy, since I have no other ideas of what's goin on here.

Thanks to everyone,