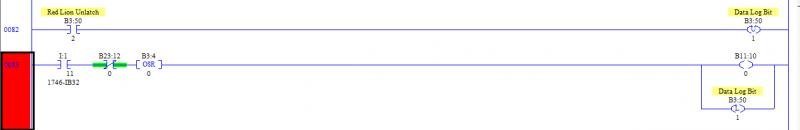

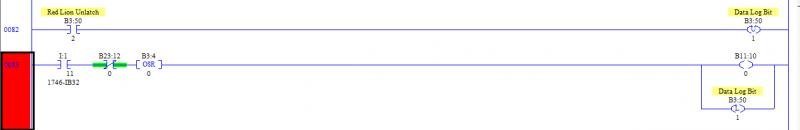

I am using bit B3:50/1 as a trigger for my data logger in crimson3.

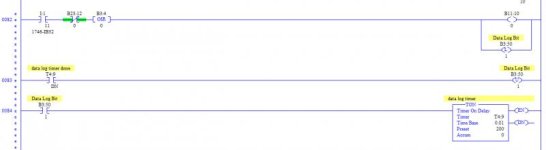

When B3:50/1 goes active on, B3:50/2 is set to 1 by crimson3. This unlatches B3:50/1. When B3:50/1 goes active off, B3:50/2 is set back to 0 by crimson3.

The past two mornings both the unltach and latch rung have shown as green. When I toggle it back to off, it begins working again.

I have the exact same setup running on another machine and it has not had any issues.

When B3:50/1 goes active on, B3:50/2 is set to 1 by crimson3. This unlatches B3:50/1. When B3:50/1 goes active off, B3:50/2 is set back to 0 by crimson3.

The past two mornings both the unltach and latch rung have shown as green. When I toggle it back to off, it begins working again.

I have the exact same setup running on another machine and it has not had any issues.