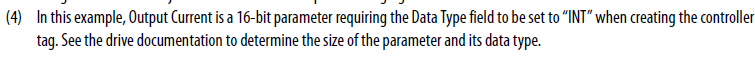

Hello, I'm trying to read a parameter from a Power Flex 525 drive to monitor output current in order to detect a jam condition in carousel filler. I'm following the handy example in Power Flex manual but am confused about the destination tag. I'm creating a tag called Output_Current but what should my data type be? With an INT it makes a tag with a + next to it and it's full of BOOLs.

I want my Output_Current to be a number so I can stick it on an HMI and look at it. Eventually, after I determine what value corresponds with a jam condition, I will use a comparison instruction to enable hard stop of the filler. I'm new to this rxlogix 5000 stuff. Will an INT data type tag work? How do I get a normal number instead of a tag full of 16 BOOLs?

Attached is the example in the 525 manual. Controller is a CompactLogix and I don't have the ability to test the project on a spare controller.

Thank you

I want my Output_Current to be a number so I can stick it on an HMI and look at it. Eventually, after I determine what value corresponds with a jam condition, I will use a comparison instruction to enable hard stop of the filler. I'm new to this rxlogix 5000 stuff. Will an INT data type tag work? How do I get a normal number instead of a tag full of 16 BOOLs?

Attached is the example in the 525 manual. Controller is a CompactLogix and I don't have the ability to test the project on a spare controller.

Thank you