hidroela

Member

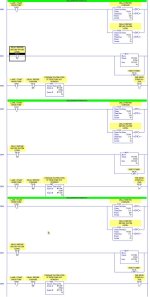

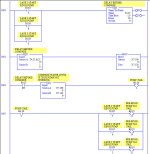

I have 3 pumps I would like to run each one for a weak at a time

In other words pump 1 this weak pump 2 next weak and pump 3

the next weak and start the cycle all over again I am using plc 5

and rslogix 5 any small ladder example would be appreciated

In other words pump 1 this weak pump 2 next weak and pump 3

the next weak and start the cycle all over again I am using plc 5

and rslogix 5 any small ladder example would be appreciated