John Morris

Lifetime Supporting Member

Good Morning to all

FTV 8.0, RSL5K,

I have set up a Multi state indicator. Its just a light, but I need it to change colors with the state of the motor.

Blue = motor off

green= motor on

red= motor in overload.

I have each of the tags set in RSL5K.

I have read several post and I think I know what to do, but please confirm

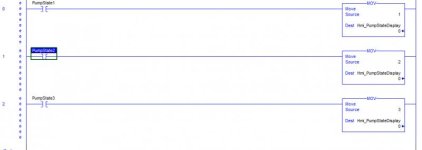

Create DINT tag in the controller and label it PUMP_MOTOR_STATUS.

Take the three tags for each condition and assign them each to a box under the DINT.

Then point the multi state indicator to the dint and whichever box lights up that's the state of the indicator.

Do I have my head wrapped around any part of this correctly?

Thanks For the time and consideration

FTV 8.0, RSL5K,

I have set up a Multi state indicator. Its just a light, but I need it to change colors with the state of the motor.

Blue = motor off

green= motor on

red= motor in overload.

I have each of the tags set in RSL5K.

I have read several post and I think I know what to do, but please confirm

Create DINT tag in the controller and label it PUMP_MOTOR_STATUS.

Take the three tags for each condition and assign them each to a box under the DINT.

Then point the multi state indicator to the dint and whichever box lights up that's the state of the indicator.

Do I have my head wrapped around any part of this correctly?

Thanks For the time and consideration