Hi Fluidpower

I am not sure if this is going to help you much, but here is a read of an analog genius block attached to a series 6 PLC (a bit old).

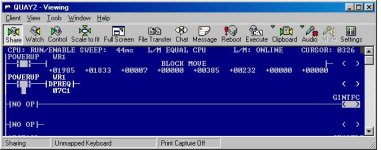

I will explain the 2 rungs shown.

Rung 1. This is a 'block move', this is the registers used for the 'data procesing request' DPREQ. We execute it this way to ensure that we are only reading the input values that we want to read, the registers in the block move are loaded with preset values to ensure that.

First we have the controlling logic to read the block, in this case we have used our 'POWERUP' bit, this bit is set after the first scan.

next we have a register address (starting address for the next seven registers) where the command block for the DPREQ is moved to.

The next seven registers (starting with the one containing the value 1833) are as follows:-

1. The bus controller address plus 1000

2. The command number, in our case 7 which means read analog status.

3. DPREQ status number - this is zeroed by the cpu, it is loaded by the bus controller at the end of the DPREQ.

4. This is the block I/O starting address (Input 385 in our case)

5. This is the register where you want the analogue data stored.

6. This is the length of the datagram being sent (if you are sending datagrams, which you won't be)

7. Not used.

Rung 2 is the data request rung, the value in hex will equal the value that is in the starting address of the registers used for the command block.

Well I am sure my explanation makes that as clear as MUD! That is obviously not one of my strong points, if you find it useful and you have any questions than ask away, perhaps Steve Bailey might be able to explain it a bit better

paul