m_reavis

Member

I am working with rslogixs 5000 controllers and have a programmer that suggest using a look up table to store and retrieve information. The idea is to control product speed on a conveyor system using the average of 50 samples and comparing it to a look up table to adjust motor speed. Below is the communication and attachment I received from him; idea’s, comments?????

Then I would use a simple 8-bit lookup table.

That means 1 to 256 ms yields a reduction or additional speed.

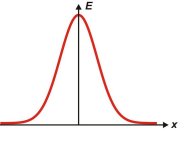

My intuition tells me a Gaussian distribution has our backup solution. See attached.

Axis X is the added speed. Axis E is the measured time. The point where the red line crosses axis E is the baseline.

Once established on a job, its a done deal for all jobs. The only variable is bottle size, which would simply load a Gaussian table with a higher or lower standard deviation (less or more peak at Axis E)

All factors would be accounted for (theoretically that is). If for example the section is small (too much blower power) or on a decline, then we run the left hand side of the Gauss table.

If the section is large or on a incline, then you ride the right side of the Gauss table.

There would only be one esoteric setup and from that point forward anyone can fill the data table on future jobs.

Ofcourse, the extremes of the X axis would be clamped by the controls not to exceed certain values.

Then I would use a simple 8-bit lookup table.

That means 1 to 256 ms yields a reduction or additional speed.

My intuition tells me a Gaussian distribution has our backup solution. See attached.

Axis X is the added speed. Axis E is the measured time. The point where the red line crosses axis E is the baseline.

Once established on a job, its a done deal for all jobs. The only variable is bottle size, which would simply load a Gaussian table with a higher or lower standard deviation (less or more peak at Axis E)

All factors would be accounted for (theoretically that is). If for example the section is small (too much blower power) or on a decline, then we run the left hand side of the Gauss table.

If the section is large or on a incline, then you ride the right side of the Gauss table.

There would only be one esoteric setup and from that point forward anyone can fill the data table on future jobs.

Ofcourse, the extremes of the X axis would be clamped by the controls not to exceed certain values.