Hi everyone,

I've got a liquid adhesive dispense valve which needs to be maintained at about 300 degrees F. Its temperature is being controlled in a ControlLogix controller, using RSLogix 5000's PIDE control block. The output of the block is a value between 0 and 1000 which determines the percentage of the time the heater will be turned on. (So if the PIDE output is 630, the heater will be on 63% of the time)

Is that commonly called time-proportioned?

Anyways, the temperature of this valve overshoots by 40 degrees or more sometimes, which is unacceptable. I've got another valve, being controlled by another controller, but set up exactly like this one, that maintains the temperature right at 300 degrees, plus or minus a few tenths of a degree. The logic is exactly the same in both controllers, and the PIDE loop setup and paramaters are exactly the same in both controllers.

I've verified the RTD shows about 100 ohms at ambient temperature, measured from the wires right at the RTD input card. I've swapped the dispense valves so that the one that was being controlled properly is now on the controller that isn't working right - problem wasn't there.

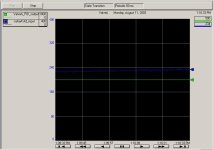

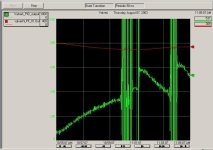

Attached is a screenshot of the trend of the one I can't get to hold 300 degrees F. The red line is the RTD input (run through a lowpass filter, since there was some degree of noise) and the green is the control variable output of the PIDE loop.

Any ideas?

I've got a liquid adhesive dispense valve which needs to be maintained at about 300 degrees F. Its temperature is being controlled in a ControlLogix controller, using RSLogix 5000's PIDE control block. The output of the block is a value between 0 and 1000 which determines the percentage of the time the heater will be turned on. (So if the PIDE output is 630, the heater will be on 63% of the time)

Is that commonly called time-proportioned?

Anyways, the temperature of this valve overshoots by 40 degrees or more sometimes, which is unacceptable. I've got another valve, being controlled by another controller, but set up exactly like this one, that maintains the temperature right at 300 degrees, plus or minus a few tenths of a degree. The logic is exactly the same in both controllers, and the PIDE loop setup and paramaters are exactly the same in both controllers.

I've verified the RTD shows about 100 ohms at ambient temperature, measured from the wires right at the RTD input card. I've swapped the dispense valves so that the one that was being controlled properly is now on the controller that isn't working right - problem wasn't there.

Attached is a screenshot of the trend of the one I can't get to hold 300 degrees F. The red line is the RTD input (run through a lowpass filter, since there was some degree of noise) and the green is the control variable output of the PIDE loop.

Any ideas?