jtashaffer

Member

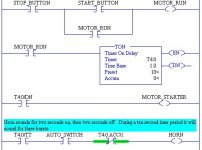

Does anyone know the best way to add a horn to a start button that stays on for 10 sec then shuts off and the motor starts.

Notice it doesn't say that the audible device has to be on CONTINUOUSLY, but that the "audible warning" must continue for a required period of time. It may seem a small point, but I have found that it is much better to sound the horn in 1.5 to 2 second bursts, separted by 1.5 seconds of quiet time, continuing for the required period of time. Then if someone IS in the equipment, you have a better chance to hear him yell, and everyone else will not get a headache listening to the loud horn. Those short pauses between blasts do wonders for employee morale - a rest before the next on-slaught. Your people who work in the area will love you for this small little change that costs nothing with a PLC program!The audible warning shall be actuated by the controller device starting the conveyor and continue for a required period of time before the conveyor starts.