Hi,

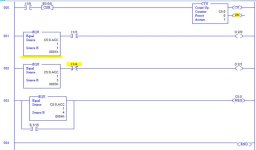

my project is to program the motor in a grage door using control relay. The thing is that I'm using only one button to make it goes up and then if I press the same button, the door should stop and when I press it for the third time, the control relay should be energized and the door should go down.

I'm using I:1 for the push button, O:0 for the motor and O:1 for the control relay. could any one post me a logixpro program that can do this.

thank you,

my project is to program the motor in a grage door using control relay. The thing is that I'm using only one button to make it goes up and then if I press the same button, the door should stop and when I press it for the third time, the control relay should be energized and the door should go down.

I'm using I:1 for the push button, O:0 for the motor and O:1 for the control relay. could any one post me a logixpro program that can do this.

thank you,